![[Translate to EN:] [Translate to EN:] matte Parkettoberfläche Eiche](/fileadmin/_processed_/2/9/csm_woodflor222_eiche_natur_nebla_shutterstock-1223792074_117620034850_a3_rgb_e0bf73f990.jpg)

What exactly has our brand new deep matt UV-lacquered surface PUROTEC to offer?

Scheucher is very proud to present its new PUROTEC surface to you:

What is this PUROTEC surface now?

It is a natural, deep matt UV lacquered surface with a gloss level below 5 without the use of massive amounts of matting agents. Thanks to a new process technology, that is unique in the parquet industry, PUROTEC creates a particularly natural look and provides your parquet with very special functionalities that stand out from all ultra matt lacquered surfaces on the market. PUROTEC is of course free of solvents and testet for a healthy living environment. Above all, the practical use of PUROTEC surface is characterized by its excellent chemical resistance and exceptionally good microscratch resistance (check our video here). It is practically maintenance-free, offers an anti-footprint effect and also has minimal changes in color caused by UV light. In addition, PUROTEC is resistant to the disinfectants and cleaning agents used in hospitals. Due to its ideal frictional properties it is also suitable for the use as a sports floor (ex works) and, in the brushed Valletta version, it meets slip class R10.

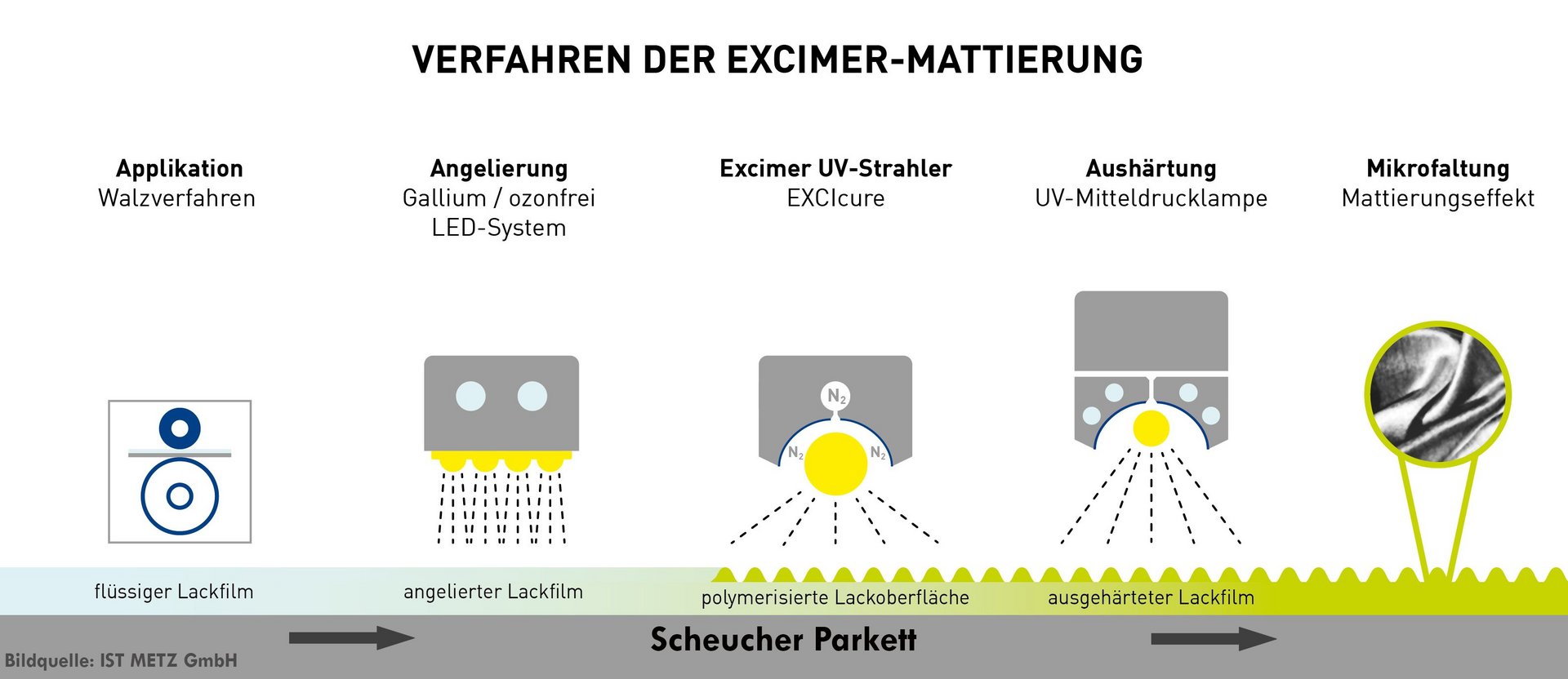

All of this is possible using a technology that is unique in the parquet industry - the inert excimer matting:

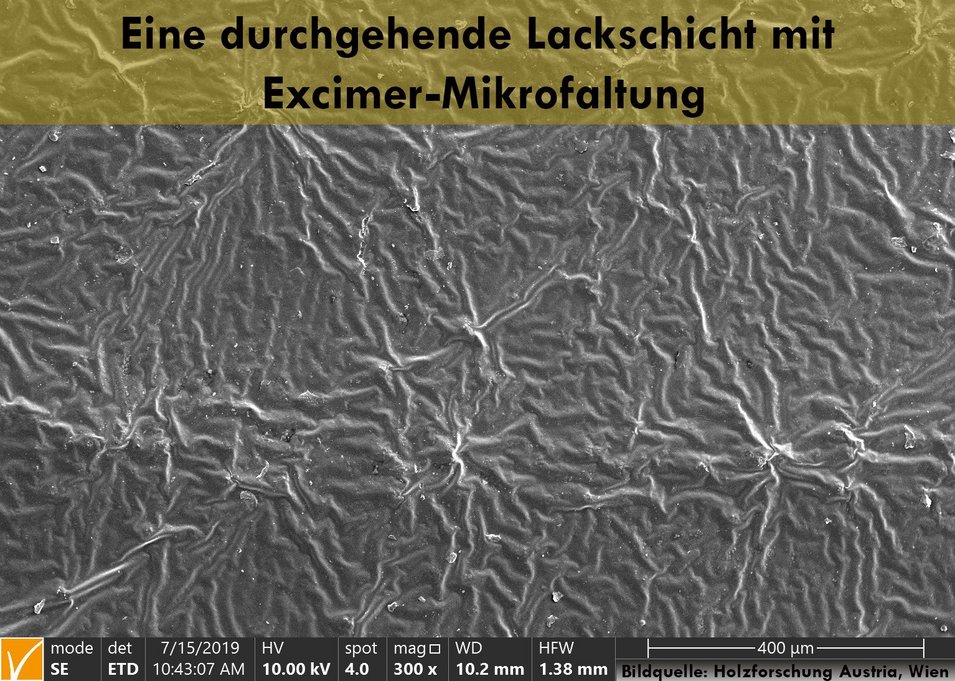

Excimer lamps emit light in the short-wave UV range at a wavelength of 172 nm, below the UV-C range. This light, which is invisible to our eyes, has a particularly high-energy emission. But since it has such short waves, the penetration capacity is very low and it can only penetrate a few µm deep into the liquid paint. The paint film, specially developed with our supplier Bona, only hardens completely on the surface and a skin forms like ice on a lake. This wafer-thin film shrinks very strongly when it hardens, which leads to micro-folds. Since the UV lacquer underneath is still liquid, it is cured to the full layer thickness together with the shrunk and micro-folded lacquer skin by subsequent classic UV lamps.

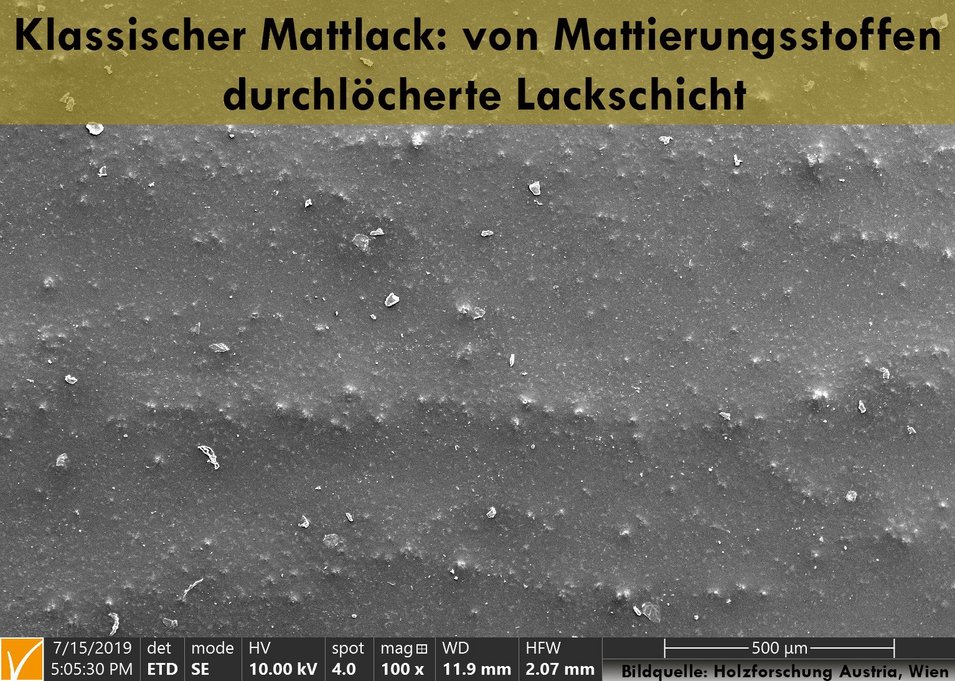

This micro-folding scatters the impinging light in all directions (diffuse reflection), which our eyes perceive as a deep matt look. To stick with the example with the lake, the main difference to matting with matting substances should also be explained briefly and boldly: While a continuous film is present with a micro-folded excimer matting, the light scattering at classic matting is achieved by matting agents, which are like footballs shot in a lake that float on top and are fixed by the freezing of the lake - just like it happens when drying with UV lamps.

If many ice skaters drive around on this lake now, they slit open the protruding parts of the footballs, then they are torn out by sliding with the runners or rolled smooth by the ice resurfacer. All of this also happens on your parquet floor with various mechanical exposures such as moving chairs, micro-scratches from street shoes or cleaning with cleaning machines. All footballs that are no longer there reduce the refraction of light, which corresponds to the poor behavior of matt lacquers against polishing. The missing footballs in the lake are weak points in the ice, which explains the reduced chemical resistance of matt lacquers, for example. Our excimer matt lacquers do not have any of these disadvantages! This has been proven by accredited test institutes, so the requirements for the highest level C of suitability for objects, scratch resistance, suitability for castors, various friction and sliding resistance tests, suitability for sports floors and of course chemical resistance and fire behavior are met in the best possible way.

Then why doesn't anyone do it?

Because the requirement for this is an oxygen-free space under the excimer lamp. Achieving this with parquet floors is an extremely high technical challenge. Parquet boards made of solid wood are not always absolutely predictable - there can possibly be some air pockets under minimal longitudinal curvatures. The tunnel must therefore have a minimum height so that the planks have enough space. This makes it even more difficult to fill this tunnel, which is open on the inlet and outlet side, with an inert gas so that the oxygen in the air is completely removed without becoming too expensive. A return on investment is of course much more difficult to calculate with an absolutely new technology and therefore represents a high risk in implementation. We are convinced that excimer matting is the technology of the future and we faced all these challenges, researched this topic for a long long time and successfully implemented it! As a special extra, we can now also produce our standard matt lacquered surface, which has been on the market for years, with a gloss level of 8-10 using excimer technology. The necessary adaptations of the processes and the lacquer were made and tested in large series. Tenseo Matt will therefore be replaced by TENSEO X-MATT from February 2022 and you will enjoy all the advantages of the new technology in the usual gloss level of our matt lacquer.

The market launch was delayed by a year due to the pandemic, but we won't let that stop us again! So if we have aroused your interest in this absolutely new technology, then we look forward to your visits to one of our partners in your area!